As the electric vehicle (EV) market continues to expand, the demand for reliable and efficient AC EV chargers is on the rise. For businesses looking to enter this lucrative market or enhance their existing offerings, partnering with the right Original Equipment Manufacturer (OEM) factory is crucial. This article delves into the key factors to consider when selecting an OEM factory for AC EV chargers, ensuring that your product meets quality standards and market demands.

Understanding AC EV Chargers

Before diving into the selection process, it’s essential to understand what AC EV chargers are and their importance in the EV ecosystem. AC EV chargers convert alternating current from the power grid into a form that electric vehicles can use to recharge their batteries. They are commonly found in residential, commercial, and public charging stations.

Importance of Choosing the Right OEM Factory

Choosing the right OEM factory can significantly impact the efficiency, reliability, and overall quality of your AC EV chargers. The right partner can help you:

- Reduce Production Costs: A reliable OEM can streamline production processes, leading to cost savings.

- Ensure Quality Control: Partnering with a reputable factory ensures adherence to industry standards and certifications.

- Foster Innovation: Working with experienced manufacturers can lead to the incorporation of advanced technologies and features in your products.

- Improve Time-to-Market: A capable OEM can expedite production, helping you respond quickly to market demands.

Factors to Consider When Choosing an OEM Factory

1. Experience and Reputation

When selecting an OEM factory, consider their experience in manufacturing AC EV chargers. Research their history in the industry, client testimonials, and case studies. A factory with a proven track record will likely understand the nuances of the EV charger market and be better equipped to deliver quality products.

2. Certifications and Compliance

Ensure that the OEM factory complies with relevant industry standards and certifications. Look for certifications such as:

- ISO 9001: Indicates a commitment to quality management systems.

- UL Certification: Ensures safety and reliability in electrical products.

- CE Marking: Confirms that products meet European health, safety, and environmental protection standards.

These certifications are crucial for gaining customer trust and ensuring product safety.

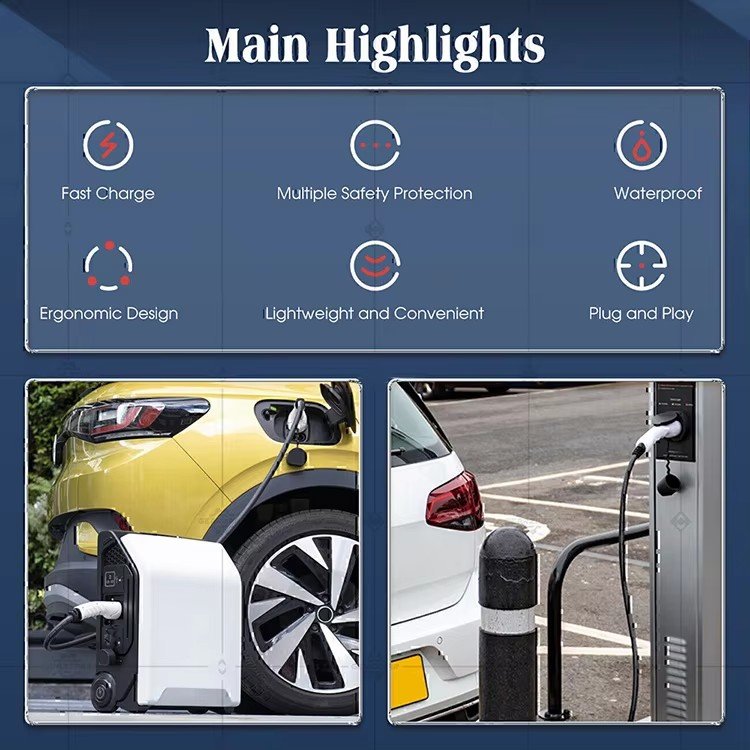

3. Technological Capabilities

Evaluate the technological capabilities of the OEM factory. The EV charger market is constantly evolving, with new technologies emerging regularly. A factory that invests in research and development can offer innovative solutions and keep your products competitive. Look for features such as smart charging capabilities, energy efficiency, and compatibility with various EV models.

4. Production Capacity and Scalability

Consider the production capacity of the OEM factory. Ensure that they can meet your current demands and scale up production as your business grows. A factory with flexible manufacturing capabilities can adapt to changes in order volume and product specifications, ensuring that you can respond to market demands effectively.

5. Location and Logistics

The factory’s location can impact logistics and shipping costs. Consider partnering with a factory that is strategically located to reduce transportation costs and lead times. Additionally, evaluate their supply chain management practices to ensure timely delivery of components and finished products.

6. Quality Control Processes

Inquire about the quality control processes in place at the OEM factory. A robust quality assurance program ensures that products are tested and meet specifications before reaching the market. Ask about their inspection processes, testing facilities, and how they handle defects or recalls.

7. Cost Structure and Transparency

Understanding the cost structure of the OEM factory is vital for budgeting and profitability. Request a detailed breakdown of costs, including materials, labor, and overhead. Transparency in pricing can help you avoid unexpected expenses down the line.

8. Communication and Support

Effective communication is crucial when working with an OEM factory. Ensure that the factory has a responsive support team that can address your queries promptly. Regular updates on production progress and proactive communication about any potential issues are essential for a successful partnership.

Building a Strong Partnership with Your OEM Factory

Once you’ve selected the right OEM factory, it’s essential to foster a strong partnership. Here are some tips:

- Establish Clear Expectations: Define your product specifications, timelines, and quality standards upfront.

- Maintain Open Communication: Regularly communicate with the factory to discuss progress, challenges, and any changes in requirements.

- Provide Feedback: Share constructive feedback on product quality and any issues that arise to help the factory improve its processes.

Conclusion

Choosing the right OEM factory for efficient AC EV chargers is a critical decision that can significantly impact your business’s success. By considering factors such as experience, certifications, technological capabilities, and quality control processes, you can make an informed choice that meets your company’s needs. A strong partnership with a reputable OEM factory will not only enhance the quality of your products but also position your business as a leader in the growing EV charger market.